Harstra newsletter

October 2024

Our recent service technician training at our factory in Zeewolde was a big success! This hands-on, 1-day course equips technicians with the skills needed to service and maintain Harstra machines effectively, ensuring optimal performance for PPE cleaning and drying.

During the training, participants gain comprehensive knowledge about our product range, troubleshoot common issues, and learn best practices for maintenance. The course covers key machines like the F12 drying cabinet, M18/M45 drying cabinets, and Wash systems 4, 6HP and 9.

With practical workshops and theory sessions, this training ensures technicians are fully prepared to handle installations and ongoing maintenance with confidence.

Click the button to learn more or to sign up for the next training.

Introducing “Meet the Team“. Each newsletter, get to know one of our Harstra employees! This month:

“Since 2003, after completing my mechanical engineering studies, I have been working at Groku in the sales & calculation department. Following the acquisition of Harstra in October 2023, I also took on responsibility for the sales side of the business at Harstra.

What I love most about my role is working closely with clients to turn ideas into reality. There’s nothing more rewarding than seeing a project come to life and having satisfied customers.

Right now, I’m focused on optimizing processes at Harstra, bringing in fresh ideas with our new team members. It’s exciting to see products ready to ship to our customers, knowing the impact they’ll make!

In my free time, I enjoy spending time with my wife and two children (aged 3 and 5). We love going on vacations to France or Italy, traveling in true Dutch style – with our caravan!

My favorite quote is “No problem, we’ll take care of it!”

I’m truly inspired by the enthusiasm and dedication of the people working in the Safety industry. They often work behind the scenes, but they make sure everyone stays safe. It’s an honor to contribute, even in a small way, to their work with Harstra’s machines.”

The F12 drying cabinet is an energy-efficient and fully automated solution designed for drying SCBAs. It features a durable stainless steel construction and consumes just 0.8 kW/h, making it cost-effective for long-term use. The standard model comes with the AF12 trolley, which holds up to 12 SCBAs.

For added functionality, you can upgrade to the AF64 Combi Trolley, which allows drying of 6 SCBAs and 36 breathing masks simultaneously, offering flexibility for different operational needs. Other trolley options, like the AF44 and AF80, provide further customization for drying masks or smaller equipment, making the F12 adaptable to various requirements.

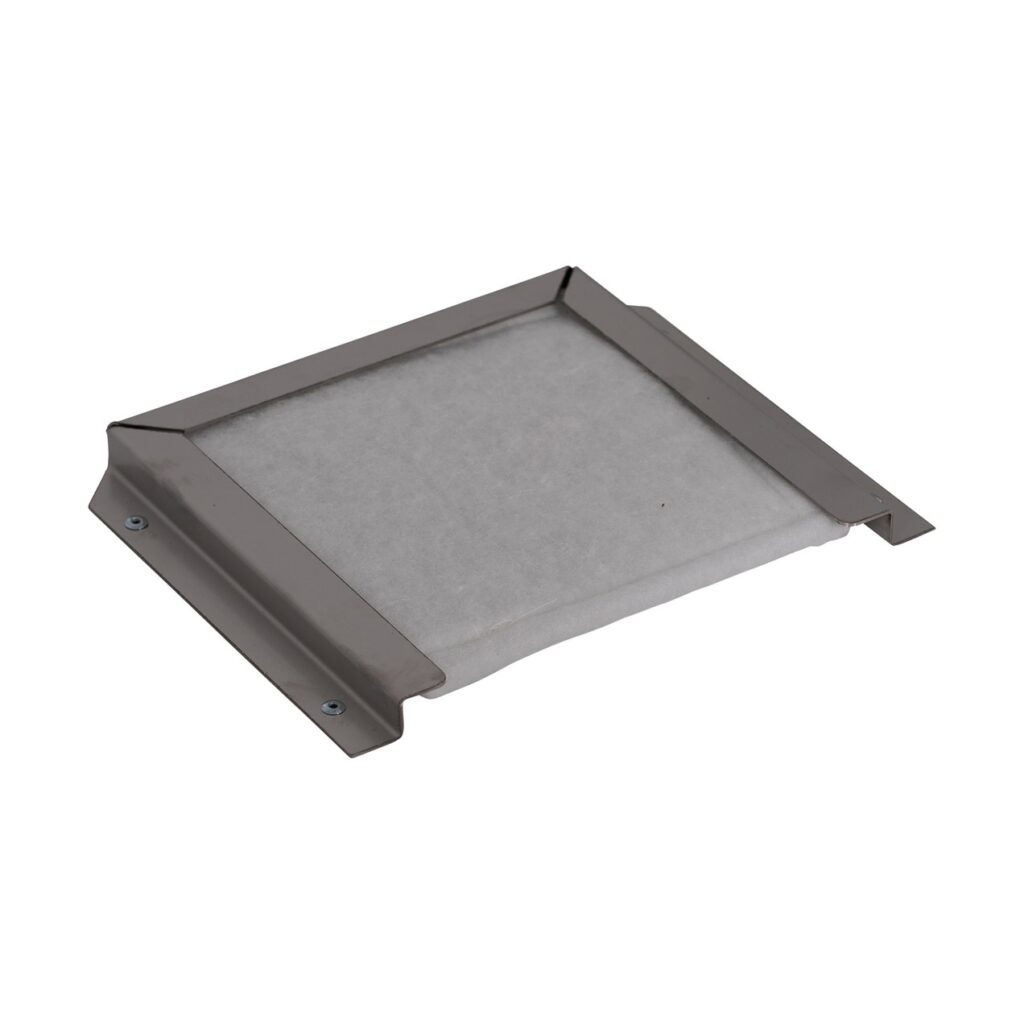

The AM15 air inlet filter is specifically designed for use in drying cabinets such as the M18, M45, K3, K6, K8, and K10 models. This filter plays a critical role in purifying the incoming air, ensuring that the drying process remains clean and efficient.

Made from synthetic fleece, the AM15 is compact with dimensions of 145 x 145 x 10 mm. It fits securely beneath the drip tray in a stainless steel holder, making it easy to install and maintain. Visit the accessories page to find out more

Share: